Unveiling a Next-Generation Robot for an Industry Stuck in Time

With Hofer Studio and LabsCubed

Lab automation startup LabsCubed set out to develop a robot that would raise the bar for materials testing equipment. Here’s how we came together to design a production-ready product that saved time and money for their discerning customers and turned investors’ heads, while showing their team how thoughtful design makes them even more innovative.

Words by Jackelyn Gill

Running a startup means wearing many hats. Research. Product. Design. Marketing. Sales. Finance. But with so much to do, sometimes you need a bit of outside help and expertise to translate your business values and goals into a finished product—especially when it’s your first. That’s what young robotics startup LabsCubed discovered when they booked space at a major industry trade show to showcase a market-changing materials testing robot—with just a prototype in hand.

“As a startup, you try to do as much as you can on your own,” says Ammar Jafar, CTO of LabsCubed. In their case, that approach was enough to build a minimum viable product of the CubeOne, a robot that automates stress and strain testing for rubber materials by stretching small samples until they break, recording the tensile strength, analyzing the tear data, and sharing the results via purpose-built cloud software. Usually, materials lab technicians do that work on manually operated machines. The fact that CubeOne does all of this automatically—and uses test data to inform new material compositions in the lab—puts CubeOne ten steps ahead of the competition.

But LabsCubed needed the CubeOne to look ten steps ahead, too - especially considering those old machines haven’t changed significantly in design or function since the 1960s. The team poured thousands of hours into building something that would prove their concept was viable. Something they could touch and feel. Something that worked. But they hit a wall. Having never brought a product to market before, and without a design expert on staff, they needed someone who could show them the ropes, from product-brand alignment and product design strategy to optimizing their manufacturing process.

“You can have the greatest idea in the world, but if you package it in something awful, it will never work,” their CEO Khaled Boqaileh shares.

Back in early 2018, the CubeOne was entirely functional, but it wasn't ready for its trade show debut.

That’s how I met LabsCubed in 2018. When Boqaileh and Jafar first reached out to me, they were looking for a one-time product redesign that would improve on their prototype to better reflect their company’s values and resonate with their customers. And it needed to happen before they made their debut at the 2018 International Elastomer Conference in Louisville, KY. “It looked like a school project. And we’re talking about a $100,000 machine that's going to sit in a customer's facility where they're selling millions of dollars’ worth of product,” Boqaileh says.

What we accomplished together was so much more: their first sale, a major round of investment, and a whole new understanding of how strong, lasting design helps them resonate with their users, become a leader in their market and excite their customers.

A startup-friendly design partner

The LabsCubed team are first and foremost engineers. As Boqaileh says, “We're aesthetically challenged, to say the least. We built something that works, but it wasn't really with much thought as to how it looked or how people would interact with it.”

The CubeOne promised to make a huge impact on the materials testing industry, but it needed a redesign if it were going to be taken seriously.

They knew they needed a design partner if they were going to attract customers and investors—someone who understood their stage of business and the pressure they were under, and who could overcome some specific challenges.

For instance, the CubeOne’s clear acrylic exterior offered visibility into the inner workings while providing a controlled test space, but with its metal frame, harsh edges, and exposed bolts, it more closely resembled an older-generation industrial machine than a modern robot with cutting-edge technology.

Because of the interior mechanisms, the prototype was awkwardly shaped, too. Like the letter “L” flipped on its back, the machine was long on one side and tall on the other, which would make shipping inefficient and costly with so much unused space in the box. User touchpoints, like the sample loading experience, needed to be simpler to prevent errors and improve safety. Developing a strategy for the materials they use and a local manufacturing process was key if they were going to produce units profitably and efficiently at low volumes. On top of that, everything needed to meet specific electrical and user safety requirements for industry certification.

Challenge accepted. LabsCubed wasn’t just reinventing a machine. They were reinventing materials testing with highly advanced technology. I saw an opportunity to help create a new, exciting brand with a team of passionate and talented engineers, with a new product that reflected their goals and values, in an industry ripe for change.

Great design connects the dots

To make sure LabsCubed and I produced the right design for their business, their customers, and their users, we followed my five-phase design methodology, which kicked off a year-long design process.

In the initial stage, Align, we got to know each other, set expectations for the project, and planned how we would work together as partners throughout its lifecycle. It was clear at this point that we were a good fit.

With a mutual understanding of the work ahead of us, we moved onto the Immerse phase, where we studied the technical architecture of the CubeOne, the underlying user values and frustrations, as well as the aspirations of LabsCubed as a company. At this stage, I received my first tour of a materials testing lab—and from the machinery on the floor to the industrial-age posters on the wall, I felt like I had stepped backward in time.

These hulking, manual machines are commonplace in materials testing labs - and are exactly what the CubeOne aims to improve upon.

My new knowledge about their users’ inputs and behaviours, product criteria and key business drivers that mattered most—like making their first sale, lowering their development and manufacturing costs, establishing credibility in the market and building a launchpad for a whole portfolio of products—led us to the Define phase, where we set specific goals for progress.

To be successful, the CubeOne would need to feel familiar to lab technicians accustomed to using the same machinery for 20 or more years, intuitive enough for new technicians to understand it at a glance, and well-executed and trustworthy enough for buyers and investors to take it seriously.

Starting with an exploration of potential manufacturing methods and the kinds of visual design they could produce, we settled on a design philosophy that prioritized user interaction and could extend to future products. I considered how to maintain visual consistency across future product lines with a design language that could translate to different machines regardless of size, orientation, or the material they test, all while looking contemporary and relevant ten or more years from now.

After showing a few initial sketch proposals to Boqaileh and his team, we worked together to refine the best solutions into a single, smart direction in the Resolve phase. We decided where we could make trade-offs in size, mechanical architecture, material costs, and user experience. In the Deliver phase, we worked both virtually and in-person with manufacturers — some from my own network — to communicate and methodically address all the production details necessary to hit project milestones.

Trade show-ready in record time

At the trade show, LabsCubed unveiled an entirely new version of the CubeOne.

Because we repositioned the internal mechanisms, the machine was no longer awkwardly shaped. Instead, the sleek rectangular unit was encased in a solid, formed metal housing. Gone was the glass exterior, replaced with a topside window that focused the user's attention on tests in progress. With no external screws visible from the front, it looked equally at home in an office as it did in a lab.

Using it was as simple as loading rubber samples into the testing tray, inserting it into the machine, and pressing the start button. A light indicated the machine’s status, and a centrally mounted tablet with purpose-built cloud-based software captured and displayed all measurement data in an easy-to-interpret dashboard, including videos of each test.

The first iteration of the CubeOne kept the functionality of the prototype but improved on the external casing, the user interface, and the materials.

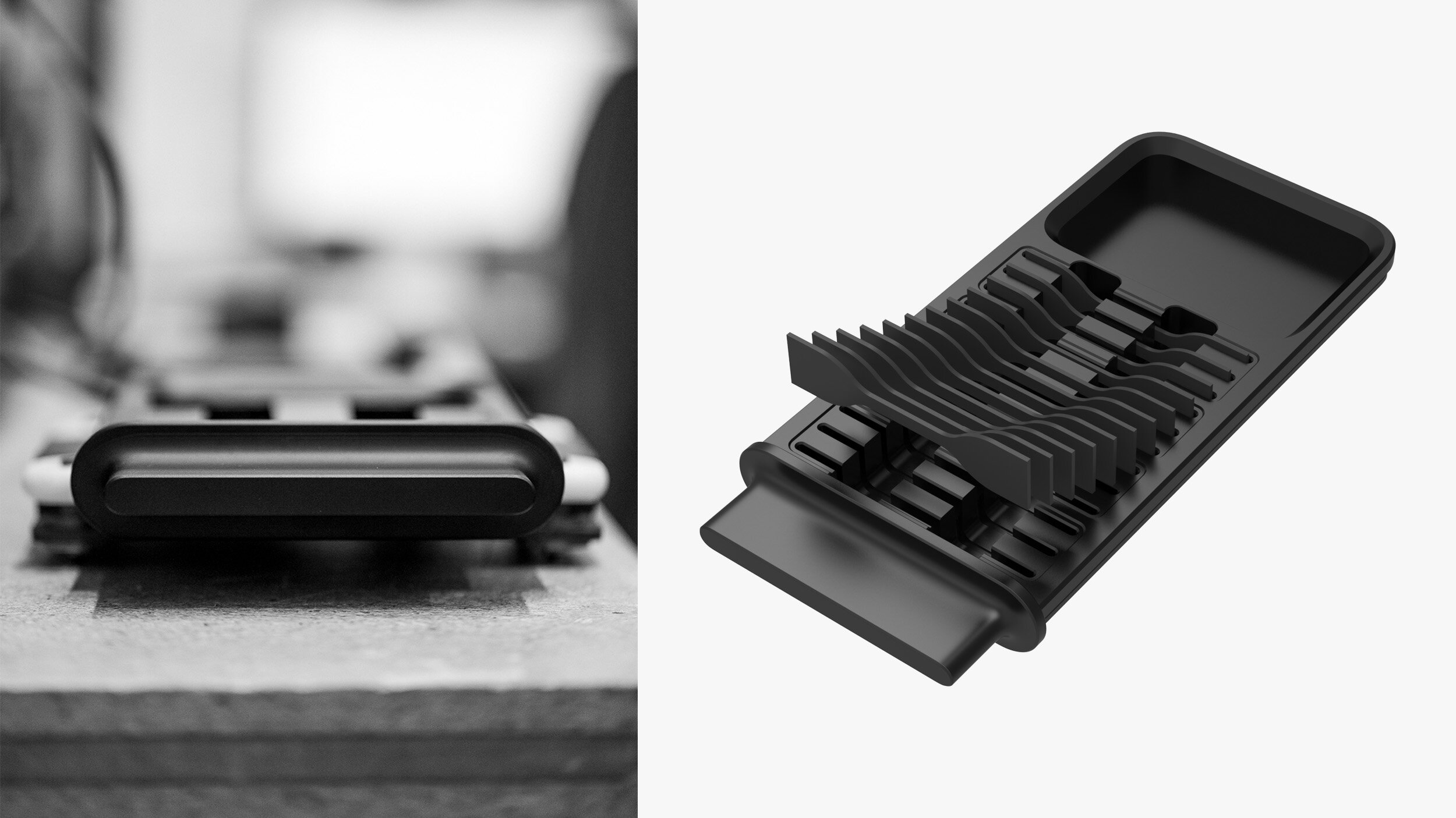

The CubeOne’s sample tray holds 12 rubber test samples and was redesigned to eliminate finger pinch-points.

It worked exactly as planned, Boqaileh adds – and the positive reaction he received made him feel like he was being taken seriously as a founder, like LabsCubed was a serious business, and like the CubeOne was a real product.

LabsCubed team and myself with the first successful beta build in Waterloo, Canada, the day before it was transported to LabsCubed's first industry trade show.

“It was a revolution in the design in terms of what we had versus what we took to the show. We made a sale at the show because of the design, and left with a lot of really solid leads,” he says.

Thinking big and small

But my work wasn’t done. Next, LabsCubed kicked off a new round of funding – this time, a big one. Our first design was resolved enough to help secure $1.2 million. Considering investors are typically apprehensive about hardware investments, that was an encouraging milestone for the whole team. With those funds, LabsCubed began thinking about their next trade show. This time, they booked a large booth where they would showcase an even more refined production version of the CubeOne.

With more time to work on improvements, we revisited the Resolve and Deliver design phases, where we focused on the finer details, like improvements to the user experience, the materials and manufacturing processes, and the overall fit and finish. We asked customers for their thoughts, and learned some valuable lessons – for example, they wanted greater visual access on the top of the unit so they could monitor tests with higher confidence.

Thinking through assembly and service sequences led to architecture breakthroughs.

The CubeOne's windows slide out, providing access to the mechanisms inside to simplify maintenance.

The design LabsCubed unveiled at the 2019 International Elastomer Conference was fully aligned with their company’s values of user simplicity, technical accuracy and enduring quality with a large, rectangular exterior in Anthracite gray, and a top-side window that ran the length of the machine. It carried forward the simplicity of its predecessor, with a single button, an indicator light, and a central monitor that showed the results of each test, but with a much deeper focus on manufacturability, improved part design, internal clearances, structural rigidity, assembly, and service procedures—all while being cheaper to manufacture.

Where the CubeOne prototype stacked internal guides vertically, the new CubeOne nested them horizontally, saving space and creating a sleeker shape.

New materials improve the cost, durability, manufacturability, and environmental footprint of the unit - since 60 per cent of the machine is composed of aluminum, it can be recycled into new products with no degradation. And speaking of footprints, moving the tablet interface to the centre of the unit minimizes footsteps for users. They can load samples, run tests, and analyze results while standing in one place.

But more than that, the new CubeOne was an anchor point for their future. It represented what LabsCubed can accomplish, the difference the brand can make, and gave the team tangible proof that everything they were working towards was finally real.

“That's where his non-obvious experience came in and was very helpful in terms of hitting the deadline that we needed to hit,” says Boqaileh. “The result is exactly what we needed, which is what our customers needed.”

A win for LabsCubed – and their customers

Success isn’t always easy to quantify, especially when you’re a startup still signing your first customers. But LabsCubed can pinpoint some clear ways our partnership has moved their business forward. Their customers are delighted with the product. It cuts preparation time to just five minutes for a batch of 36 samples, and the results are ten times more consistent with little to no human error. Plus, with less repetitive manual work involved, technicians can focus their time on other priorities in the lab while the tests run automatically.

A seamless user interface connects the hardware and software.

It’s also become a symbol of innovation for customers. “When their customers come in to look at the labs, they tour them around our machine to show that they’re doing something futuristic and evolving their lab’s capability,” says Boqaileh.

The innovative design has earned the CubeOne two distinctive design awards, from both the European Product Design Awards, one of the highest international forms of recognition a product design can receive, and PLAST-EX and the Advanced Design & Manufacturing Expo’s inaugural Startup Stadium Competition, further demonstrating the robot’s potential as an innovative, ground-breaking machine.

And while they still aren’t designers themselves, LabsCubed now thinks about design—and the value it awards their business—in a new way. “Joseph really changed our philosophy in terms of looking at it as a holistic product. Not just the engineering aspect of it, but how customers interact with it. That's a very different mindset.”

A far cry from the 1960s industrial aesthetic of current materials testing equipment, the CubeOne sets a new materials, construction, and aesthetic direction for the LabsCubed brand.

Jafar perfecting the final CubeOne in the LabsCubed lab, making many improvements to both the hardware and the software.

The CubeOne measures 127cm (50in) wide, 55.8cm (22in) deep, 38cm (15in) tall, and is 73.5kg (162lbs).

If you would like to discuss ways design could impact your business outcomes, set up a Free Discovery Call with Joseph Hofer here.